Zinc Electroplating Corrosion Protection

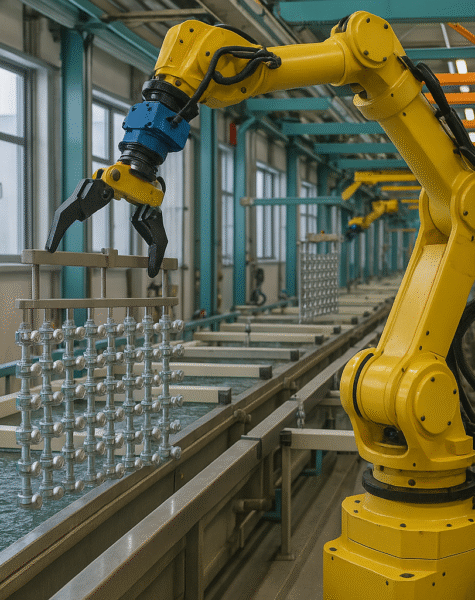

Neochrome’s zinc plating creates a sacrificial barrier that prevents rust formation on ferrous metals. Our automated barrel lines process high volumes of fasteners and small components with consistent 5-25μm coatings. We offer multiple chromate options including clear, blue, yellow, and black finishes to enhance corrosion resistance and appearance.

Our trivalent chromate technology provides RoHS-compliant alternatives to traditional hexavalent systems without sacrificing performance. All zinc-plated components undergo post-plating baking to prevent hydrogen embrittlement. We provide salt spray certification up to 500 hours based on chromate selection and thickness.

Salt spray protection: 96-500+ hours

Hydrogen embrittlement relief baking

Color-coded corrosion protection

Chromate Options

Technical Capabilities

Industry Applications

- Clear: 96-144 hours protection

- Blue: 144-240 hours protection

- Yellow: 240-500 hours protection

- Black: 144-336 hours protection

- Rack plating: 0.3-25μm

- Barrel plating: 5-15μm

- Hydrogen baking: 375-400°F

- Trivalent alternatives available

- Automotive fasteners

- Electrical enclosures

- Agricultural equipment

- Structural hardware

Contact

- Hassan Bin Haitham Street, Industrial Area 2, Ajman, U.A.E

- +971 52 916 8740+971 55 388 4167

- alanan786@yahoo.comneochrome10@yahoo.com