Metal Pre-Treatment Specialists

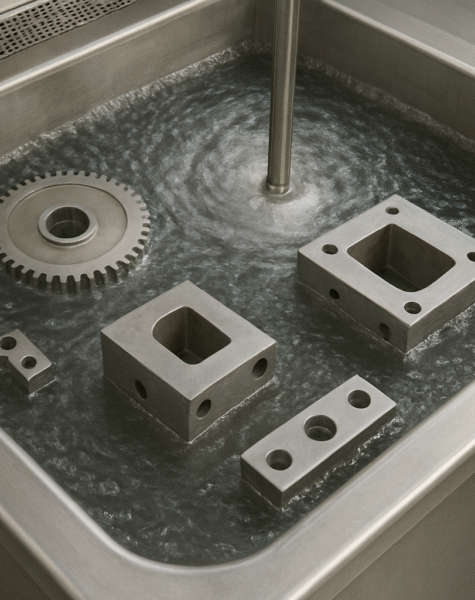

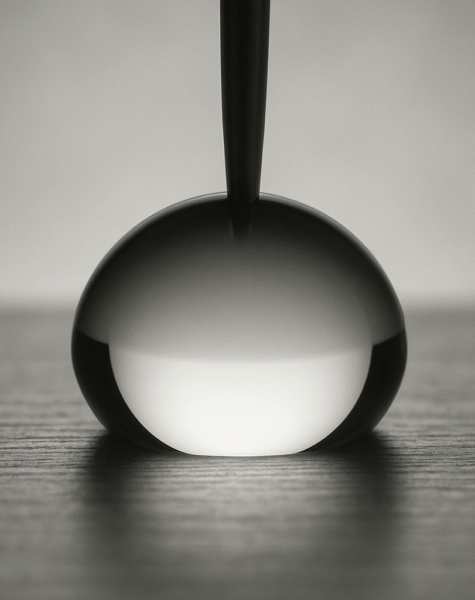

Proper surface preparation is essential for coating performance. Our multi-stage cleaning processes include alkaline degreasing, acid pickling, ultrasonic cleaning, and activation to ensure perfect substrate readiness. We perform surface energy verification through water break tests and contact angle measurement.

Neochrome’s contamination analysis includes SEM/EDS for identifying oils, oxides, and incompatible conversion coatings. We specialize in hydrogen embrittlement relief baking for high-strength alloys and complex geometries. Our proprietary processes restore contaminated surfaces to plating-ready condition.

Ultrasonic cleaning to 40kHz

Hydrogen embrittlement relief

Surface energy >72 dynes/cm

Cleaning Methods

Activation Processes

Quality Validation

- Alkaline soak cleaning

- Vapor degreasing

- Ultrasonic (40kHz)

- Electrocleaning

- Acid pickling

- Desmutting

- Activation dips

- Mechanical abrasion

- Water break testing

- Contact angle measurement

- Wipe tests

- SEM/EDS analysis

Contact

- Hassan Bin Haitham Street, Industrial Area 2, Ajman, U.A.E

- +971 52 916 8740+971 55 388 4167

- alanan786@yahoo.comneochrome10@yahoo.com