Precision Nickel Electroplating Solutions

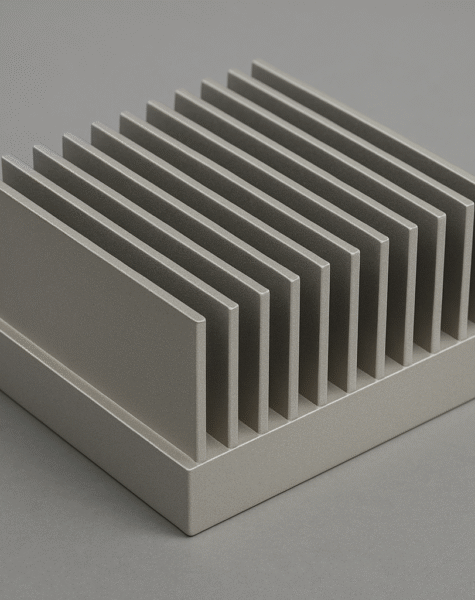

Our nickel plating services provide exceptional corrosion barriers with salt spray resistance exceeding 500 hours. We offer both sulfamate nickel for low-stress applications and electroless nickel for uniform coverage on complex geometries. With phosphorus content control (2-12%), we engineer deposits for specific hardness, magnetism, and solderability requirements.

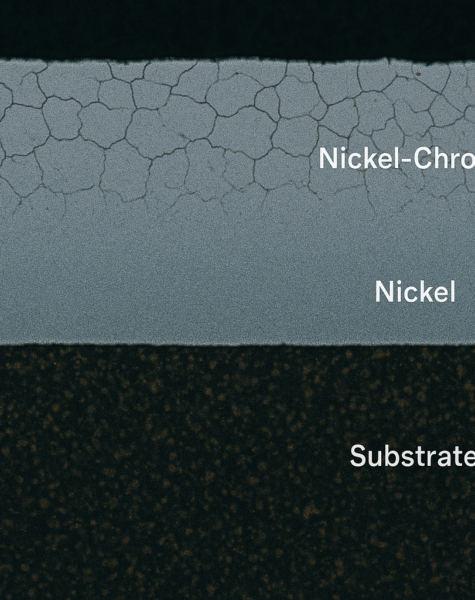

Neochrome’s proprietary multilayer systems combine nickel with specialty undercoats for enhanced protection. Our bright nickel finishes deliver luxury appearances for consumer goods, while matte finishes serve functional applications. All processes include post-plating baking to prevent hydrogen embrittlement in high-strength substrates.

0.0001"-0.005" thickness range

98%+ deposit uniformity on complex parts

RoHS-compliant chemistries

Process Variants

Technical Advantages

Compliance Standards

- Watts nickel for general protection

- Sulfamate for low internal stress

- Electroless for complex geometries

- Composite coatings with PTFE/SiC

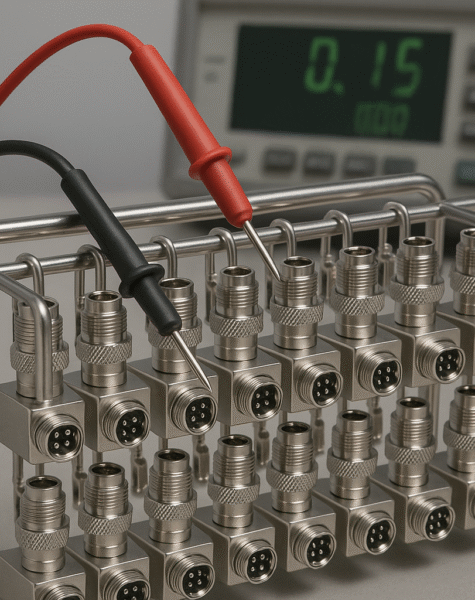

- Vickers hardness: 300-700 HV

- Porosity: <1 pinhole/cm²

- Solderability within 2 seconds

- Thermal stability to 800°F

- ASTM B733 compliant

- MIL-C-26074 certified

- ISO 4527 electroless spec

- FDA-compliant for food contact

Contact

- Hassan Bin Haitham Street, Industrial Area 2, Ajman, U.A.E

- +971 52 916 8740+971 55 388 4167

- alanan786@yahoo.comneochrome10@yahoo.com