Industrial Chrome Plating Services

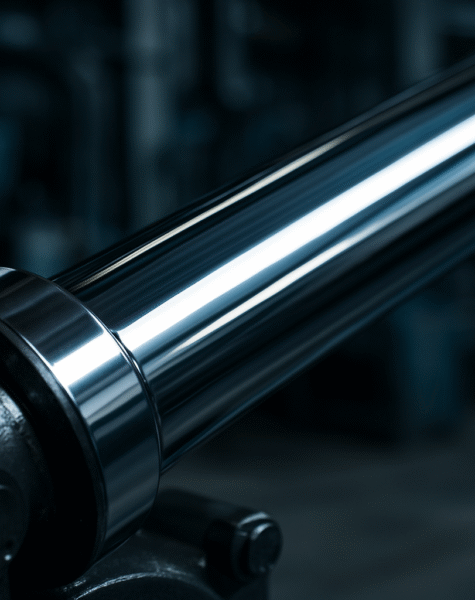

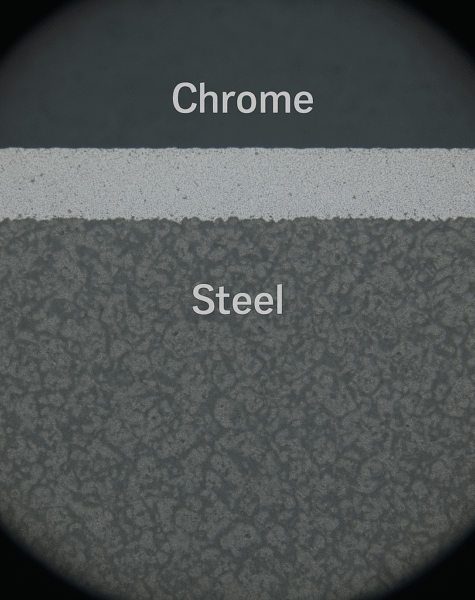

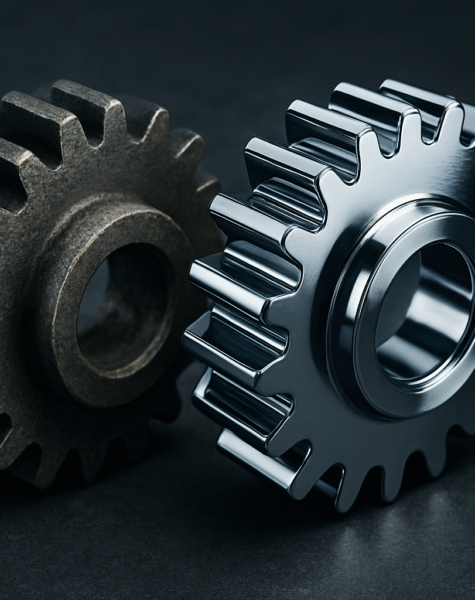

Neochrome’s hard chrome plating delivers unparalleled surface hardness (70+ HRC) for components subjected to extreme wear. Our proprietary deposition process creates low-porosity coatings that withstand abrasive environments while maintaining dimensional accuracy. We achieve micron-precise thickness control (±0.0001″) for critical applications in aerospace hydraulics and industrial machinery.

Beyond functional applications, our decorative chrome plating provides mirror finishes for automotive trim and consumer goods. Utilizing trivalent chromium technology, we offer environmentally compliant solutions that exceed ASTM B177 standards while delivering brilliant luster. All processes include hydrogen embrittlement relief baking for high-strength alloys.

- Coating thickness: 0.0001"-0.020"

- Surface hardness: 68-72 HRC

- Adhesion strength: 10,000+ PSI

- Salt spray resistance: 96-500+ hours

- Aerospace landing gear components

- Plastic injection molding cores

- Food processing machinery

- Marine hydraulic systems

- Daily Hull cell testing

- Microhardness verification

- Adhesion testing per ASTM B571

- Certified mil-spec documentation

Contact

- Hassan Bin Haitham Street, Industrial Area 2, Ajman, U.A.E

- +971 52 916 8740+971 55 388 4167

- alanan786@yahoo.comneochrome10@yahoo.com